When you call Unistrut Service Company inquiring about pricing or placing an order, our team members are trained to ask what are you plan to do with the material.

We ask, in part, out of curiosity (many of us build projects with Unistrut) and in part to ensure that the material ordered is right for your application. Although both of these explanations make sense, we have yet another motivation for pursuing this line of questioning, and once you hear the answer, you’ll be sure to explain your application if we don’t ask. Here’s why….

For illustration purposes, let’s assume you employees cut the strut to length, add fittings, and create an assembly used in a finished product.

Now ask yourself this question—where do your people create the most value, cutting strut into sections and putting together an assembly, or doing something else? Imagine an alternative scenario where finished, strut based assemblies arrive at your facility, and your employees incorporate each unit into a finished product. Depending on your annual usage requirements, labor costs, and in-house capacity/capabilities, outsourcing your assembly work may make sense.

Using our production saw, which can cut up to 500 pieces of channel per hour while holding tolerances of 1/16”, also saves clients significant chunks of labor time—and money. For example, earlier this year, a new customer ordered a large quantity of Telespar. When the same client called the following month, we probed further about the material’s use and learned they were cutting Telespar sticks to custom length and discarding the drops. By bringing the cutting operation in-house, we optimized material usage, eliminated scrap, reduced freight costs, and saved our client 10% on material and 20% in labor costs. Utilizing our service center capabilities allowed our client to focus on their core competencies rather than cutting and deburring sticks of 24F12.

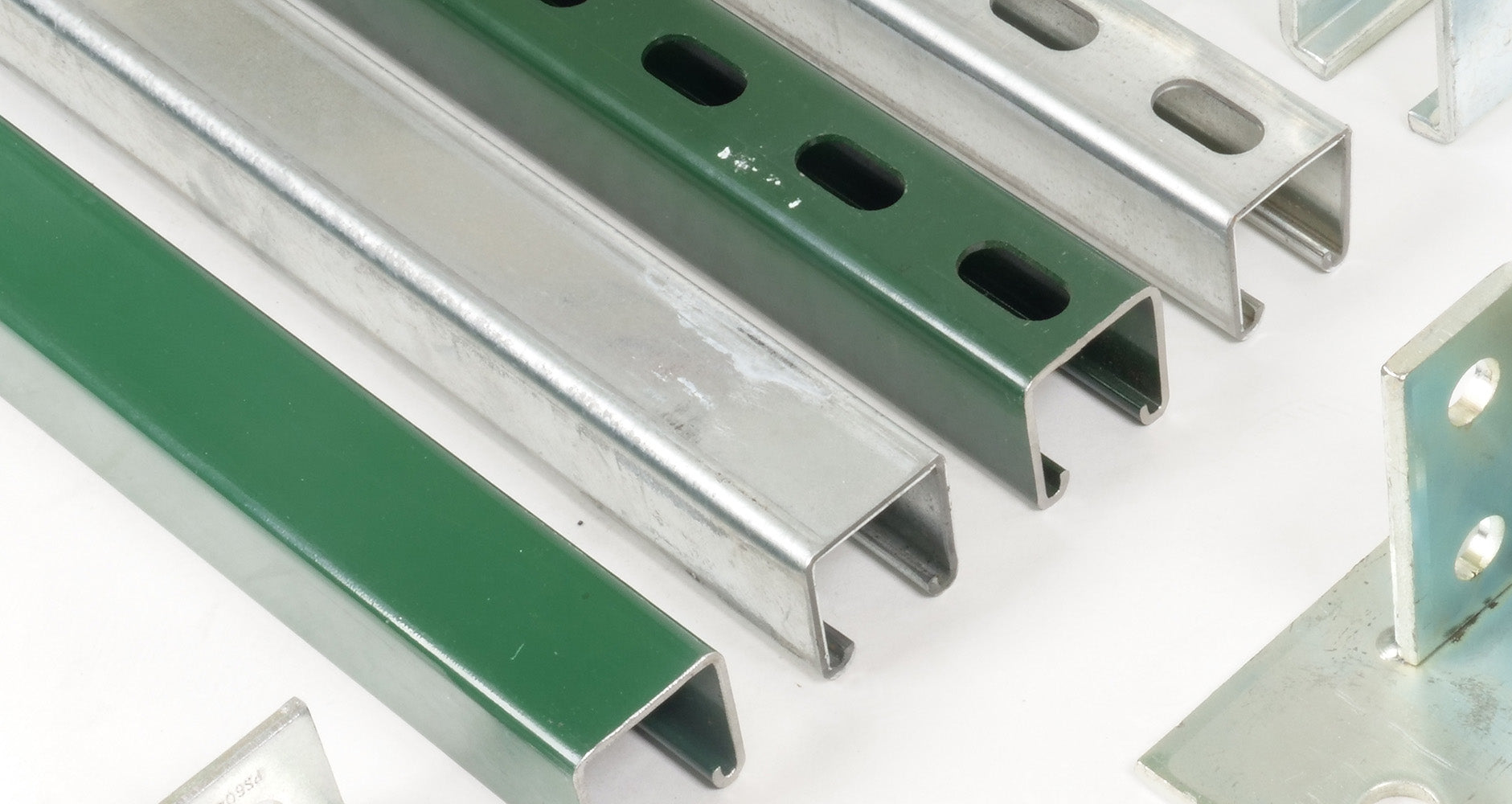

The moral of the story here is twofold. On the buying side of the equation, don’t assume you have a complete understanding of every supplier’s capabilities. And as a vendor, it’s important to approach every sale as an opportunity to educate clients on the full breadth of your capabilities. The Unistrut system has an industry reputation for saving countless hours on job sites, but of equal or greater importance is the value our people bring to the table. By asking questions about how you intend to use your material, we can recommend solutions that our clients haven’t considered. Sometimes this takes the form of substituting one fitting or channel style for another, while in other cases, we suggest utilizing our service center or engineering capabilities to improve your bottom line.

We appreciate that for most of our customers, there simply aren’t enough hours in the day to get everything done. That said, the next time one of our application specialists asks how you plan to use your material, take a few moments to explain your project—you’ll be glad you did. To learn more about getting the most out of the Unistrut system, or to discuss an upcoming project, contact Unistrut Service Company for further assistance.