OEM Metal Framing Solutions

The Most Important Part Is Your Custom Part

Original Equipment Manufacturers can’t afford delays, inconsistency, or inflexible suppliers. When your production depends on precision and reliability, the smallest part can become the biggest problem. That’s where partnering with Unistrut Service Company comes in.

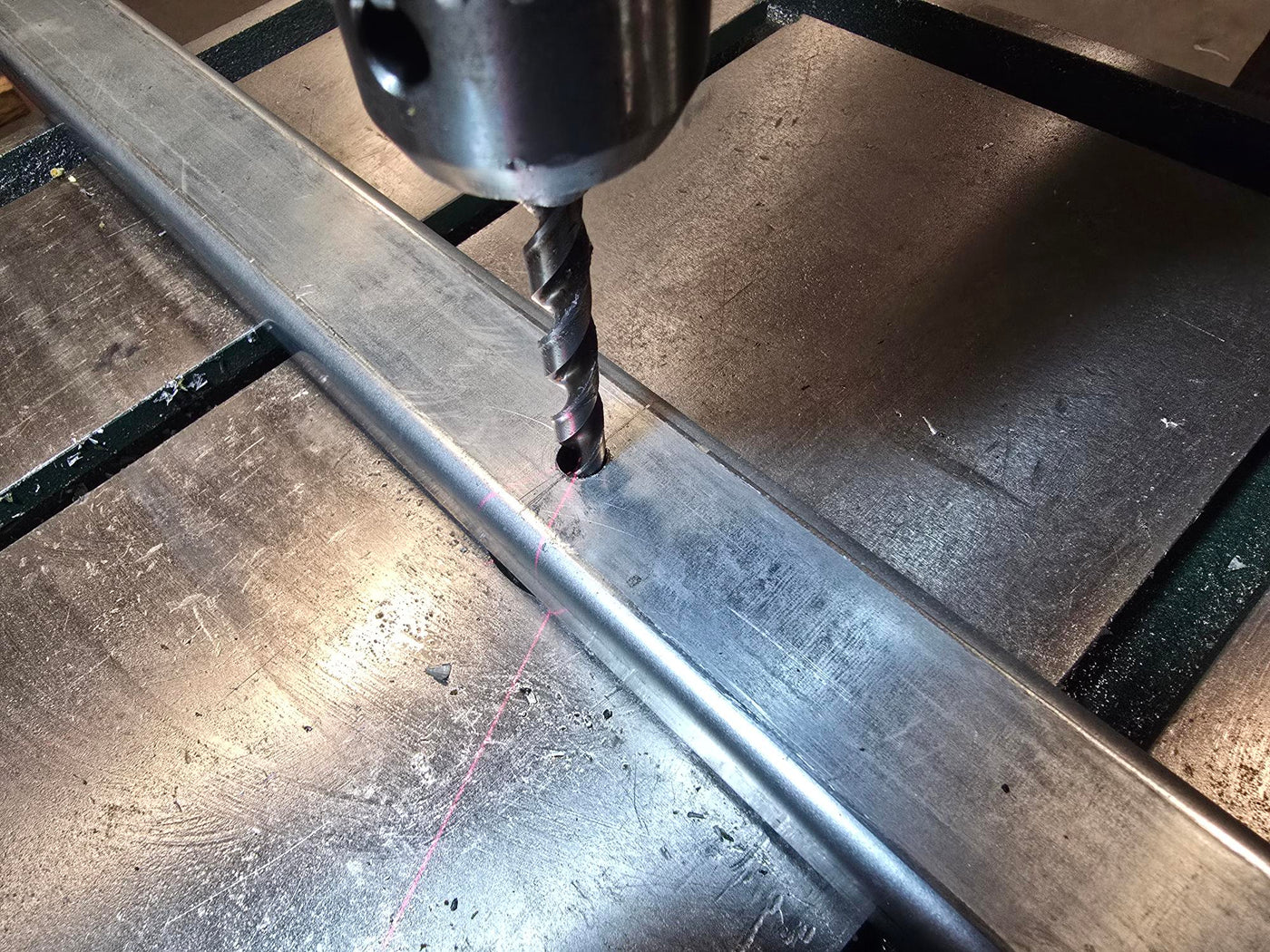

We don’t just ship metal framing. We cut, kit, fabricate, powder coat and deliver custom Unistrut metal framing solutions designed for OEM production environments — done fast, done right. Our team understands how critical your part is to your process.

OEM Pain Points USC Solves

Downtime and Delays: Tight manufacturing schedules leave no room for late shipments or fabrication errors. USC’s pre-cut, pre-assembled, and fully documented components arrive ready to use — eliminating rework and bottlenecks.

Design Changes and Variability: Your products evolve, and your framing systems should too. Our modular Unistrut solutions can adapt quickly to design revisions without welding, saving you engineering time and keeping you in production.

Inventory Concerns: We help you reduce on-hand inventory through JIT and Kanban programs, maintaining stocked materials that support your line while freeing up your floor space and cash flow.

Quality Assurance: Every component must meet repeatable, testable standards. USC’s fabrication and inspection processes ensure dimensional accuracy, consistent finishes, and predictable performance — batch after batch.

Complex Support Needs: From enclosures and conveyors to racking and automation assemblies, our engineers design for real-world integration so your custom Unistrut parts install cleanly and perform reliably.

Connect with Unistrut

Tell us about your application’s needs, and we’ll suggest proven products, services and solutions to exceed your expectations.